Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Hi Guest. Welcome to the new forums. All of your posts and personal messages have been migrated. Attachments (i.e. images) and The (Old) Classifieds have been wiped.

The old forums will be available for a couple of weeks should you wish to grab old images or classifieds listings content. Go Here

If you have any issues please post about them in the Forum Feedback thread: Go Here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Daytona Build

- Thread starter LordGeorge

- Start date

LordGeorge

Members

- May 15, 2015

- 131

- 29

- Thread starter

- #62

Quick update

Got to the tools Saturday , many many cuts later and had all modifications done in just over 3 hours.

Had the kit locktighted to shugar and lubed up Bretty dam good.

Had about 20 shots before I had to pop out and it kicks like a horse.

Will report on all the work needed to get it to fit, pics of course.

One thing I wanted to ask is the valve refresh time.

When firing the pressure in the regulator drops , obviously .. But how much is normal? If I full auto at 100psi it would hold roughly 70psi until I let off.

Cheers

Got to the tools Saturday , many many cuts later and had all modifications done in just over 3 hours.

Had the kit locktighted to shugar and lubed up Bretty dam good.

Had about 20 shots before I had to pop out and it kicks like a horse.

Will report on all the work needed to get it to fit, pics of course.

One thing I wanted to ask is the valve refresh time.

When firing the pressure in the regulator drops , obviously .. But how much is normal? If I full auto at 100psi it would hold roughly 70psi until I let off.

Cheers

LordGeorge

Members

- May 15, 2015

- 131

- 29

- Thread starter

- #63

Build log...

Sorry for the image spam

Start removal of material for rear valve.

Removed material, functional but not tidy. Will polish up soon.

IGL feed drilled ready for new pistil grip coming. "Stark-One Ar-15"

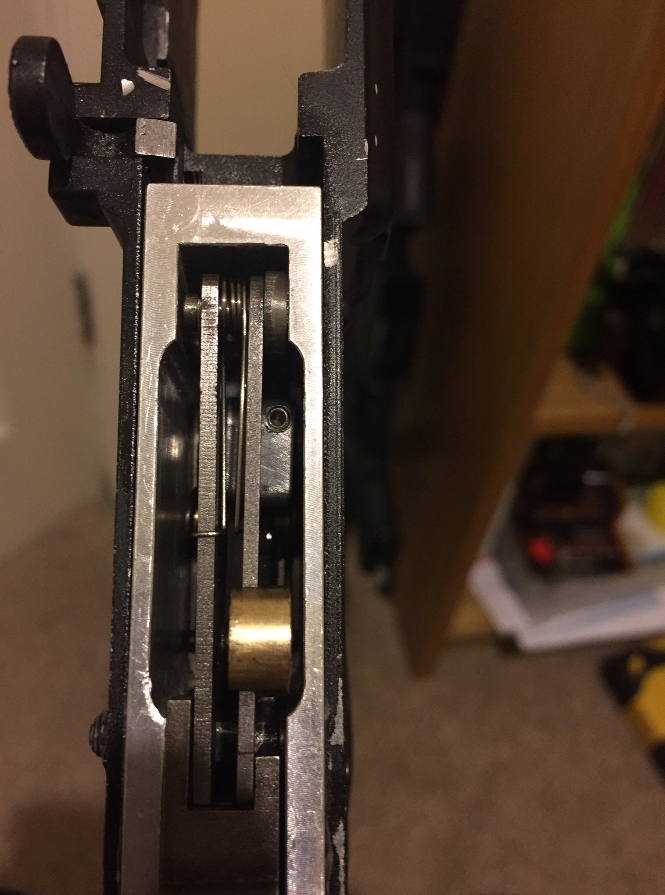

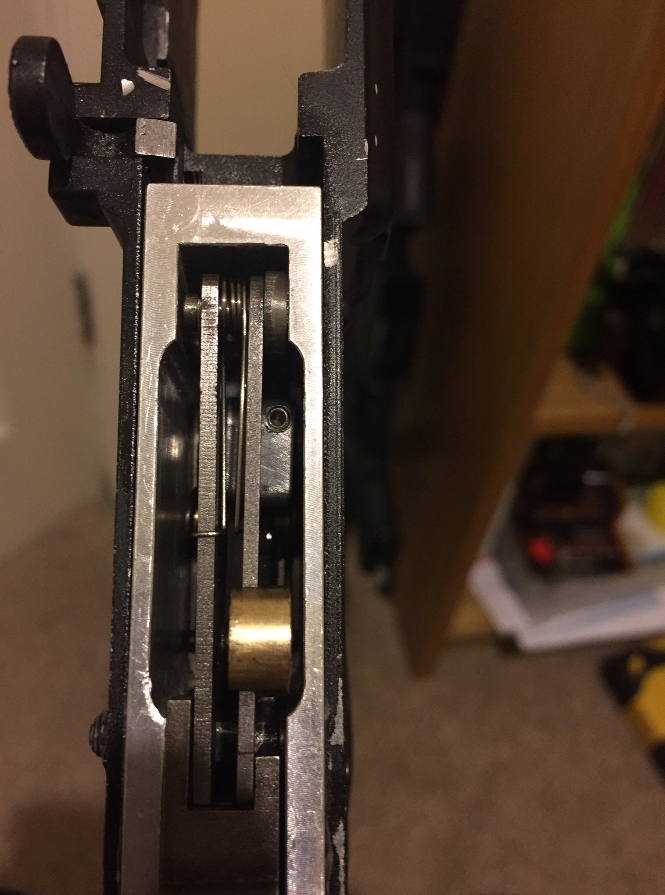

Valve mock up

Upper receiver rear lug removed.

Hopup access hole. "So happy with this drill"

Charging hangle ground down and widened for pickup.

Front access removed for hopup mag feed. Also note the bolt catch has been removed.

Sorry for the image spam

Start removal of material for rear valve.

Removed material, functional but not tidy. Will polish up soon.

IGL feed drilled ready for new pistil grip coming. "Stark-One Ar-15"

Valve mock up

Upper receiver rear lug removed.

Hopup access hole. "So happy with this drill"

Charging hangle ground down and widened for pickup.

Front access removed for hopup mag feed. Also note the bolt catch has been removed.

LordGeorge

Members

- May 15, 2015

- 131

- 29

- Thread starter

- #65

Cheers man, little rough around the edges but its getting thereNice job. Is that a real steal charging handle?

Its not, just the standard hk416. I am however tryng to get my hands on a rainier arms charging handle.

Really like the look of a ambidextrous, charging handle. want to replace the selector and trigger with real steel aswell.

Only trouble with that is i would need to buy the entire trigger kit even if i only want the trigger. Meh !

Also didnt pop up the pics of the selector, i had to shave about 1mm off the semi auto section as it was causing the full auto shear to hold on full auto in semi ^_^ .

LordGeorge

Members

- May 15, 2015

- 131

- 29

- Thread starter

- #66

George Something received the package ! B)Daytona Gun Group FAQ on FB. It's basically where 70% of the questions about DG can be answered. I think I mentioned it here or the other thread.

Yeh, I have got a few of them. PM me your address and I'll pop a couple in the post.

Cheers dude, sorting the inner barrel out tomorrow. As i havent made my mind up on the rail and outer barrel i wont buy the magnus untill 100% happy.

LordGeorge

Members

- May 15, 2015

- 131

- 29

- Thread starter

- #67

Not too much happened for a few days, had a slight slip up with the hopup rubber. Lucky tony sent me a spare are part of my order

Temporary inner barrel is cut down and in.

However i did notice that thr fps is a bit weird, not sure if you can shed some light on this "profrink" ?

So 80psi, .25 and 280-300 fps.. then 100psi 300-310 fps.

130psi, no change.

A few things i did check, the airseal when carrier is in the receiver to barrel is not great.

I can blow down the barrel, and easily lets air pass through. I moved the air rod along and it does open up fully when the cylinder opens up.

Is this just a bed in thing or should i be looking out for something ?

Cheers

Temporary inner barrel is cut down and in.

However i did notice that thr fps is a bit weird, not sure if you can shed some light on this "profrink" ?

So 80psi, .25 and 280-300 fps.. then 100psi 300-310 fps.

130psi, no change.

A few things i did check, the airseal when carrier is in the receiver to barrel is not great.

I can blow down the barrel, and easily lets air pass through. I moved the air rod along and it does open up fully when the cylinder opens up.

Is this just a bed in thing or should i be looking out for something ?

Cheers

- Oct 20, 2012

- 5,106

- 1,679

You should be getting a somewhat significant jump in FPS. Problem I have with my M249 is there's no semi and it can double feed what with still breaking in so I have to fire a few bursts to get a true reading as many come out of the barrel much slower than they should.

Does sound like an air issue though. First thing to do would be to remove the kit, connect it to your air and then put it in a sink full of water - if there are bubbles there's a leak (duh). Next is just a full disassembly (if you've not already) and reassembly with thread lock. The grub screws on the airshaft collar seem to cause a lot of issues for people, but obviously your engine is quite a bit different to mine so the FB page may be best for this (just search first).

Does sound like an air issue though. First thing to do would be to remove the kit, connect it to your air and then put it in a sink full of water - if there are bubbles there's a leak (duh). Next is just a full disassembly (if you've not already) and reassembly with thread lock. The grub screws on the airshaft collar seem to cause a lot of issues for people, but obviously your engine is quite a bit different to mine so the FB page may be best for this (just search first).

Last edited by a moderator:

LordGeorge

Members

- May 15, 2015

- 131

- 29

- Thread starter

- #69

Little update, been busy and not too much to on the TNK, i did however get my Stark pistol grip.

It’s outstanding, very strong and extremely comfortable.

The two main modifications to make it all fit was, the drill as per for the airline and widening the spring guide slot to take the original spring. Also worth noting the spring guide needed boring out around the opening to allow any misalignment on the spring and pin to not cause any selector issues.

Final fitting

It’s outstanding, very strong and extremely comfortable.

The two main modifications to make it all fit was, the drill as per for the airline and widening the spring guide slot to take the original spring. Also worth noting the spring guide needed boring out around the opening to allow any misalignment on the spring and pin to not cause any selector issues.

Final fitting

LordGeorge

Members

- May 15, 2015

- 131

- 29

- Thread starter

- #71

Two side notes.

One. Still breaking in the kit as its just too loud to do in the house and garden at times so really struggling. May take it to the local shop and use their range if they dont mind the noise.

Getting around 250fps on .25's @90psi. Still no gain at higher psi so hoping the break in will shed some light on it. "only at around 3000 rounds atm."

Two. Decided to go all in on the HPA community and have a polarstar jack coming to convert my WE Mk17, after playing with hpa gives me no love for AEG anymore.

Considering the spare parts and batteries I may very well get another AEG in the future just for the sake of having one.

Want to make some plans for tidying the paintwork on the receivers once its all done, also got a real steel ambidextrous selector favourited.

Also got some flat headed grub M3 screws coming to do the trigger job to the daytona. Currently the trigger has a long travel before it even starts pushing on the valve, so got some screws to adjust it back to the point a small flick and its off.

Only really noticed how bad the travel was when i tried spamming semi auto, you would end up flicking the trigger around and never firing .

.

Cheers

One. Still breaking in the kit as its just too loud to do in the house and garden at times so really struggling. May take it to the local shop and use their range if they dont mind the noise.

Getting around 250fps on .25's @90psi. Still no gain at higher psi so hoping the break in will shed some light on it. "only at around 3000 rounds atm."

Two. Decided to go all in on the HPA community and have a polarstar jack coming to convert my WE Mk17, after playing with hpa gives me no love for AEG anymore.

Considering the spare parts and batteries I may very well get another AEG in the future just for the sake of having one.

Want to make some plans for tidying the paintwork on the receivers once its all done, also got a real steel ambidextrous selector favourited.

Also got some flat headed grub M3 screws coming to do the trigger job to the daytona. Currently the trigger has a long travel before it even starts pushing on the valve, so got some screws to adjust it back to the point a small flick and its off.

Only really noticed how bad the travel was when i tried spamming semi auto, you would end up flicking the trigger around and never firing

Cheers

Last edited by a moderator:

- Oct 20, 2012

- 5,106

- 1,679

I'm still only about 5k into my break-in because of the fact that it's so loud, heh.

Good that it's going well. I'm considering making some sort of HPA system for a DMR to replace the one I sold next year. Possibly SMP, but the new PDiKs looks good as it doesn't require an FCU.

Good that it's going well. I'm considering making some sort of HPA system for a DMR to replace the one I sold next year. Possibly SMP, but the new PDiKs looks good as it doesn't require an FCU.

LordGeorge

Members

- May 15, 2015

- 131

- 29

- Thread starter

- #73

Haha yeah, i didnt hear too great things with the mancraft gear. Mainly its assembly and mechanics but no FCU is why the daytona was so great.I'm still only about 5k into my break-in because of the fact that it's so loud, heh.

Good that it's going well. I'm considering making some sort of HPA system for a DMR to replace the one I sold next year. Possibly SMP, but the new PDiKs looks good as it doesn't require an FCU.

I got a 800mha 7.4v for the jack so when i ever do use it, battery power shouldnt be a issue

With my low fps issue i have got a feeling that its to do with my barrel.

When i first dis-assembled the hopup i may have pulled the barrel before unscrewing the hop nut!

Intially when i took it all appart i found the hop lug nut had bent the hop window when tring to remove it... Ooops. It was straightened out and looks fine.

With this in mind i am wondering if even the smallest bend has caused pressure loss hop/barrel.

I dont mind too much as it was a learing curve but i wanted to get the orga barrel after christmas so was not planning to get it yet. Suppose i may have to break the bank a little more and have it over and done with.

Any thought's ?

- Oct 20, 2012

- 5,106

- 1,679

It's possible your bucking had just slipped or something - mine rotated almost 90 degrees after the first 500 shots! I'm still having to clock in almost 130psi to hit the equivalent of 350 with mine but it's a 500mm wide bore so I'm losing air like crazy anyway.

The parts will shift a lot during break in. Are you being sure to tighten well and putting loctite on the parts? If you need to get it apart you can use a heat gun (though be careful if you're getting that much heat near the bucking).

Depends on how it performs regarding the ORGA barrel. If it's working like you want it then a barrel upgrade is probably pointless. If not, grab one as it's the final variable here after you've broken it in.

The parts will shift a lot during break in. Are you being sure to tighten well and putting loctite on the parts? If you need to get it apart you can use a heat gun (though be careful if you're getting that much heat near the bucking).

Depends on how it performs regarding the ORGA barrel. If it's working like you want it then a barrel upgrade is probably pointless. If not, grab one as it's the final variable here after you've broken it in.

LordGeorge

Members

- May 15, 2015

- 131

- 29

- Thread starter

- #75

Well what i am thinking is that evena slight bend in the barrel is causing the high pressure to flow out of this area. The more pressure the more that passes the bucking. I had a very similar issue with my MK17 a while back and that was a bucking leak hop to barrel that only showed its face when allot of air is introduced.It's possible your bucking had just slipped or something - mine rotated almost 90 degrees after the first 500 shots! I'm still having to clock in almost 130psi to hit the equivalent of 350 with mine but it's a 500mm wide bore so I'm losing air like crazy anyway.

The parts will shift a lot during break in. Are you being sure to tighten well and putting loctite on the parts? If you need to get it apart you can use a heat gun (though be careful if you're getting that much heat near the bucking).

Depends on how it performs regarding the ORGA barrel. If it's working like you want it then a barrel upgrade is probably pointless. If not, grab one as it's the final variable here after you've broken it in.

How do you get on the the 500mm ? I was looking at that for the mk17 since getting the jack, "which is awsome btw".

I gotta get something to drop the fps on the jack, at 60psi i am getting 350fps with normal hop on. Want to drop it so i can use heavier bbs with orga.

Yep, really the only parts i have locktighted is the collar andthe carrier inner/outer screw. All else has been up tight which no apparent issues.

- Oct 20, 2012

- 5,106

- 1,679

Hm, well honestly if you have a brass or steel barrel bending isn't an issue unless you've really given it some welly. Aluminium seems to be what buckles easiest.Well what i am thinking is that evena slight bend in the barrel is causing the high pressure to flow out of this area. The more pressure the more that passes the bucking. I had a very similar issue with my MK17 a while back and that was a bucking leak hop to barrel that only showed its face when allot of air is introduced.

How do you get on the the 500mm ? I was looking at that for the mk17 since getting the jack, "which is awsome btw".

I gotta get something to drop the fps on the jack, at 60psi i am getting 350fps with normal hop on. Want to drop it so i can use heavier bbs with orga.

Yep, really the only parts i have locktighted is the collar andthe carrier inner/outer screw. All else has been up tight which no apparent issues.

Usual fix is Teflon tape both over the barrel (between the bucking and barrel) and then a couple of wraps around the bucking itself (not where the actual nub is). You should absolutely not be losing pressure though - the DGs have incredibly well machined hop units that clam very tightly onto the barrel. Last thing I could suggest is maybe checking your R-Hop if you ended up doing one as those - in theory - should provide a near-perfect air seal if you've done it properly.

Loctite everything at some point. I'm dreading doing it, but I need to completely disassemble and reassemble mine as that's recommended during break-in to get a full clean and re-lube. when it goes back together it's getting the red stuff not the blue.

Did you do the water test and make sure you have no air leaks anywhere?

Also, the 500mm seems alright. Like I said, high air consumption as I have to run at around 130psi, but as it's damn near impossible to get a straight answer out of the FB group I'm not sure if that's bad or not. I may cut a coil or two to reduce recoil and up the fps (so I can drop the pressure to bring it back to 1.17J), but I dunno.

Last edited by a moderator:

LordGeorge

Members

- May 15, 2015

- 131

- 29

- Thread starter

- #78

Also, the 500mm seems alright. Like I said, high air consumption as I have to run at around 130psi, but as it's damn near impossible to get a straight answer out of the FB group I'm not sure if that's bad or not. I may cut a coil or two to reduce recoil and up the fps (so I can drop the pressure to bring it back to 1.17J), but I dunno.Hm, well honestly if you have a brass or steel barrel bending isn't an issue unless you've really given it some welly. Aluminium seems to be what buckles easiest.

Usual fix is Teflon tape both over the barrel (between the bucking and barrel) and then a couple of wraps around the bucking itself (not where the actual nub is). You should absolutely not be losing pressure though - the DGs have incredibly well machined hop units that clam very tightly onto the barrel. Last thing I could suggest is maybe checking your R-Hop if you ended up doing one as those - in theory - should provide a near-perfect air seal if you've done it properly.

Loctite everything at some point. I'm dreading doing it, but I need to completely disassemble and reassemble mine as that's recommended during break-in to get a full clean and re-lube. when it goes back together it's getting the red stuff not the blue.

Did you do the water test and make sure you have no air leaks anywhere?

Also, the 500mm seems alright. Like I said, high air consumption as I have to run at around 130psi, but as it's damn near impossible to get a straight answer out of the FB group I'm not sure if that's bad or not. I may cut a coil or two to reduce recoil and up the fps (so I can drop the pressure to bring it back to 1.17J), but I dunno.

Yep well i had to do this to my mk17, got a aluminium madbull barrel tighbore 6.03. I r-hop'd that and also added a small bit of teflon mainly due to the WE freak of a hopup unit lol

I was considering tefloning the DG up as something tells me that will help, i will do r-hop but only on new barrel.

Well i did the same thing, tight and small amounts of locktight until break in is done then stick that shite together like crazy. Im already having to locktight external attachments and rail screws as it a shaker

I did indeed check for any leaks and there was none to report, everything seems to function well, my gut feeling is hop/barrel.

Hmm will see what to do with that, the mk17 is built as a DMR so R-hop with widebore sounds pretty sexy, im sure some retailer is going to have a little laugh when i order in almost 200 big ones for barrels alone haha.

Doing DG trigger job tomorrow, sick of sloppy trigger. Also got plans for Mk17 but most likely just fill in the case to force the trigger to rest on the switch as the trigger is too small to drill and tap.

Not yet due, only had it today so early days. Either way i will most likely get a orga for that as wellHave you tried reducing the volume of air supplied to the jack (per shot)? Via the FCU settings.

Pretty much doing all the stupid things like max fps, and rof :lol: . Funny as hell listening to a fart sounding blare from it going at 60+ a second.

Got ages untill my next skirmish due to work and Christmas, so lots of time to mess about and tweak.

LordGeorge

Members

- May 15, 2015

- 131

- 29

- Thread starter

- #79

Done the trigger job on ther DG, nothing better than drilling a £300+ kit part.

Worked out pretty well, brought its own issues once installed though.

Two things, one. In safe the shears are still able to push the valve back, hence premature evacuation of air.

Two. The small tappet on the semi auto shear catches the DG shell due to its longer travel, easy enough fixable though.

Worked out pretty well, brought its own issues once installed though.

Two things, one. In safe the shears are still able to push the valve back, hence premature evacuation of air.

Two. The small tappet on the semi auto shear catches the DG shell due to its longer travel, easy enough fixable though.

Similar threads

- Replies

- 21

- Views

- 727

Share: